This represents conveyors that have a unique purpose which is applied to make the transportation and accumulation conveyors function as an integrated system. These specific conveyors are not typically “high volume” as the transportation and accumulation conveyors, but they are essential to any automated order fulfillment system.

Unscramblers / Singulators / Pallet Layer Descramblers

This technology is used to ensure there is a single file stream of items on a conveyor prior to some consolidation of flow in the system (a merge) or a decision point of re-direction in the system (a sorter). Unscramblers and singulators are typically used to separate occasional side-by-sides in a conveyor system or to consolidate bulk items into a single stream of product in a conveyor system. A pallet layer descrambler is another variation of this technology that is used to descramble, singulate, edge align, and sometimes correctly orient full pallet layers of product into single file.

Pallet Layer Descrambler (Image courtesy of Intralox)

Brake Metering Conveyors

This technology is typically used prior to merges and sorters in a conveyor system. Individual lanes which consolidate to a single takeaway would be controlled by turning on and off the brake metering conveyors as the control point in the merge. Brake metering conveyors also typically separate items by a fixed speed change between two belts. As items move from the slower first belt, to the faster second belt, a gap is pulled and photo-electric sensors can measure the item length. This data is used in the system control. Often brake metering conveyors are used to ensure a certain minimum gap prior to induction onto a sorter.

Curves and Junctions

The technology used to articulate a conveyor line around a curve is often similar to the technology used to create a junction conveyor. Used often in a conveyor system when products are changing direction and it is desired to maintain the orientation of the item (i.e. the long dimension of the item is in the direction of travel).

Merges

While a merge is really comprised of an entire system including hardware, control devices and software, the technology used to consolidate the conveyor lines and take-away the items away in a single line of flow is often referred to as the merge. There are several types of merge technologies.

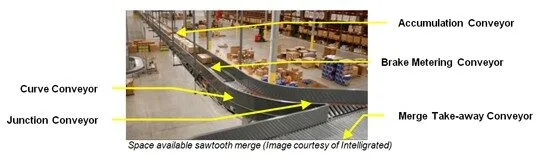

Sawtooth Merge

One of the more popular technologies is sometimes referred to as a “sawtooth” merge where the perpendicular take-away conveyor would be a roller or belt transportation conveyor. A sawtooth merge may be controlled with “space available” logic where the merging conveyor looks for a window of opportunity large enough to fit the next carton. It may also be controlled with a “timed release” of each merging lane to balance the flow of materials from several conveyor lines.

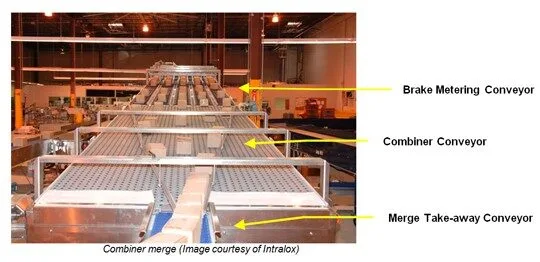

Combiner Merge

Another popular technology is a “combiner” merge where parallel conveyor lines feed a wide merge which combines the items prior to discharge. The take-away conveyor will typically be parallel to the infeed lines. Very high rates can be achieved with a combiner if products are released one at a time (or “zippered” together).

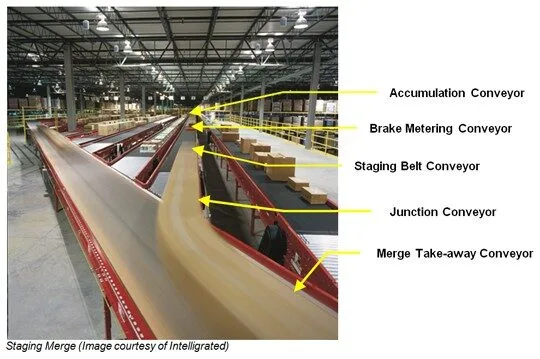

Staging Merge

At first glance, a staging type merge may look very similar to a sawtooth merge. However, a staging merge can achieve much higher rates by building long slugs of gapped product from a conveyor line on a staging belt. The staging belt then awaits its turn in the upper control merge priority before ramping up to a higher speed and delivering a dense packed stream of product.