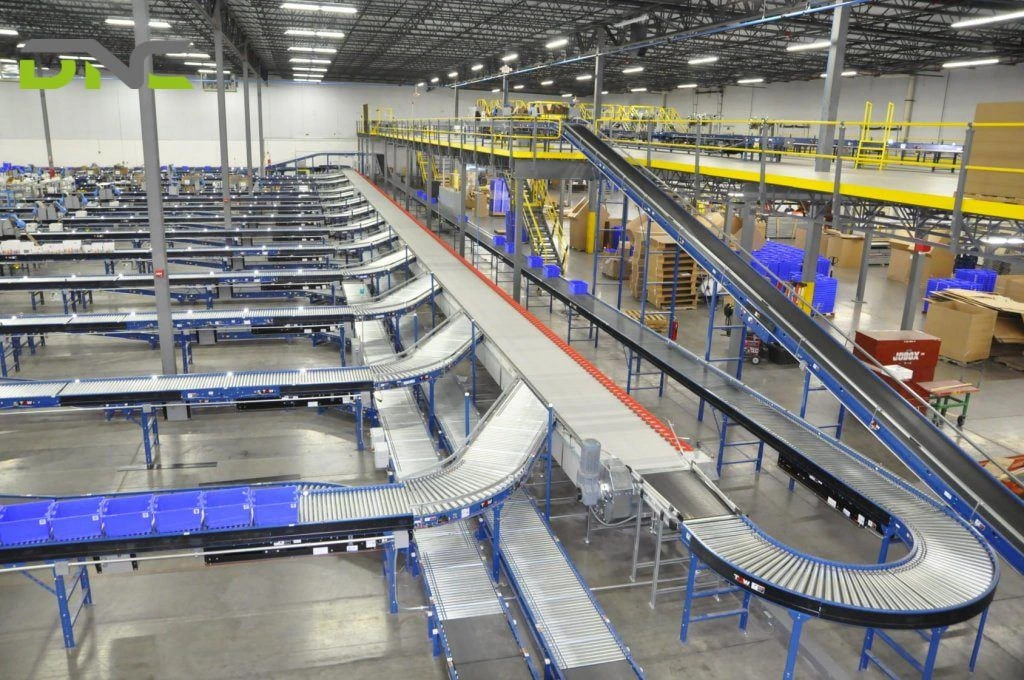

Custom Parcel Sorting Systems. Engineered for Real Operations.

-

Automatic Sorting machine

- Automatic Sorting machine

- Automatic Sorting machine

- Automatic Sorting machine

- Automatic Sorting machine

Sorting Independent equipment- Automatic Sorting machine

- Automatic Sorting machine

- Automatic Sorting machine

Spare Parts / Sorting Trolley- Automatic Sorting machine

- Automatic Sorting machine

- Automatic Sorting machine