Choosing between ocean freight, air freight, and rail transport directly impacts:

-

Cash flow

-

Delivery speed

-

Customer satisfaction

-

Inventory turnover

-

Overall competitiveness

Yet many businesses still select shipping methods based on habit, vague advice, or price alone—often learning the real cost only after problems arise.

This guide breaks down how to choose the right transportation method based on real business scenarios, not theory. Whether you’re shipping consumer goods, industrial products, or time-sensitive orders, this article will help you make smarter, more profitable logistics decisions.

1. Why There Is No “Best” Shipping Method—Only the Right Match

Each transportation mode has:

-

Clear strengths

-

Predictable weaknesses

-

Ideal use cases

Problems happen when businesses:

-

Use air freight for low-margin goods

-

Use ocean freight for urgent replenishment

-

Use rail without understanding route limitations

The goal is alignment, not optimization in isolation.

2. Understanding the Three Core Transport Options

Before matching scenarios, you need a clear understanding of what each method actually offers.

Ocean Freight: The Backbone of Global Trade

Key characteristics:

-

Lowest cost per unit

-

Highest capacity

-

Longest transit time

Typical transit time:

-

Asia → US/Europe: 20–45 days (port to port)

Cost structure:

-

Container-based (FCL/LCL)

-

Port fees, documentation, inland trucking

Best for:

-

Bulk goods

-

Low to medium value products

-

Non-urgent shipments

Ocean freight moves over 80% of global trade volume for a reason—but it requires planning and patience.

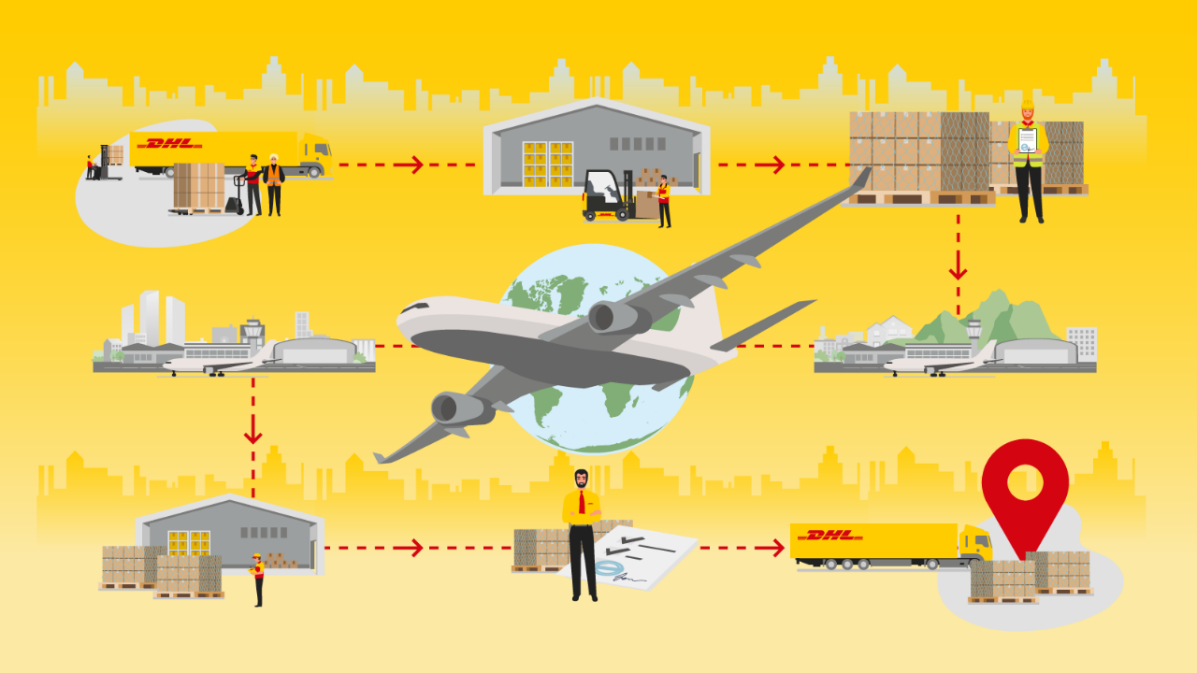

Air Freight: Speed at a Premium

Key characteristics:

-

Fastest delivery

-

Highest cost

-

Limited capacity

Typical transit time:

-

3–10 days door-to-door

Cost structure:

-

Charged by actual weight or volumetric weight

-

Fuel surcharges and security fees

Best for:

-

High-value goods

-

Time-sensitive orders

-

Emergency replenishment

Air freight is not just faster—it’s a risk management tool when time matters more than cost.

Rail Transport: The Middle Ground

Key characteristics:

-

Faster than ocean

-

Cheaper than air

-

Route-dependent

Typical transit time:

-

China → Europe: 15–25 days

Cost structure:

-

Container-based

-

Border handling and customs fees

Best for:

-

Stable trade lanes

-

Medium urgency shipments

-

Businesses balancing cost and speed

Rail is often misunderstood—but when used correctly, it can be highly strategic.

3. Step One: Start with Product Characteristics

Your product determines more than you think.

Product Value per Unit

-

Low-value goods → ocean freight

-

High-value goods → air or rail

Shipping cost should never exceed a reasonable percentage of product value.

Size and Weight

-

Heavy, dense goods favor ocean or rail

-

Lightweight, compact goods can justify air freight

Volumetric weight is often the hidden cost killer in air transport.

Fragility and Sensitivity

-

Fragile or high-risk items benefit from faster transit

-

Long ocean voyages increase exposure to humidity and handling

4. Step Two: Define Your Delivery Time Requirements

Ask a simple question:

What happens if this shipment arrives late?

Non-Urgent Inventory Replenishment

If delays cause:

-

No lost sales

-

No contractual penalties

Ocean freight is usually the best choice.

Sales-Driven Deadlines

If late delivery means:

-

Missed promotions

-

Stockouts

-

Customer complaints

Rail or air freight may be justified—even at higher cost.

Emergency or Critical Shipments

When delays mean:

-

Production stops

-

Contract breaches

Air freight becomes the only logical option.

5. Step Three: Understand Your Cash Flow and Inventory Strategy

Logistics decisions are also financial decisions.

Ocean Freight and Cash Flow

Long transit times mean:

-

Capital tied up in inventory

-

Slower inventory turnover

Best for businesses with:

-

Strong cash reserves

-

Predictable demand

Air Freight and Cash Efficiency

Higher transport cost but:

-

Faster sales cycle

-

Lower inventory holding cost

Often used strategically, not continuously.

Rail as a Cash Flow Compromise

Rail allows:

-

Faster turnover than ocean

-

Lower cost than air

Ideal for businesses scaling internationally.

6. Step Four: Consider Market and Customer Expectations

Different markets tolerate different delivery speeds.

B2B vs B2C

-

B2B customers prioritize reliability

-

B2C customers prioritize speed and tracking

This distinction often determines transport choice.

Regional Expectations

-

North America: speed-driven

-

Europe: balance of cost and sustainability

-

Emerging markets: cost-sensitive

Understanding customer mindset prevents misalignment.

7. Scenario-Based Matching Guide

Scenario 1: Low-Margin Consumer Goods

Best choice: Ocean freight

Why: Cost control matters more than speed

Scenario 2: Seasonal Products

Best choice:

-

Ocean freight for base inventory

-

Air freight for peak replenishment

Hybrid strategies reduce risk.

Scenario 3: New Product Launch

Best choice: Air freight initially

Why: Market testing and fast feedback

Scale later with ocean or rail.

Scenario 4: Europe-Bound Shipments with Moderate Urgency

Best choice: Rail transport

Why: Balanced cost and speed

Scenario 5: Spare Parts or Critical Components

Best choice: Air freight

Why: Downtime costs exceed shipping cost

8. Risk Management and Reliability Considerations

Transport mode also affects risk exposure.

Ocean Freight Risks

-

Port congestion

-

Weather delays

-

Longer exposure to damage

Air Freight Risks

-

Capacity shortages

-

Higher regulatory scrutiny

Rail Transport Risks

-

Border delays

-

Route instability

Choosing the right mode reduces—not eliminates—risk.

9. Sustainability and Compliance Factors

Sustainability is becoming a decision factor.

-

Ocean and rail emit less CO₂ per unit

-

Air freight has the highest carbon footprint

Some buyers now factor emissions into logistics choices.

10. Cost Comparison Is Not Just About Freight Rates

True logistics cost includes:

-

Inventory holding cost

-

Stockout risk

-

Customer satisfaction

-

Operational flexibility

The cheapest option on paper may be the most expensive in reality.

11. Building a Flexible Transport Strategy

Smart businesses don’t choose one method—they build options.

-

Primary mode + backup mode

-

Split shipments

-

Dynamic routing

Flexibility is a competitive advantage.

12. Questions to Ask Before Making a Decision

-

What is the true cost of delay?

-

How predictable is demand?

-

How sensitive is the product?

-

What does the customer expect?

-

Can I switch modes if conditions change?

Clear answers lead to confident decisions.

Conclusion: Match the Mode to the Mission

Ocean freight, air freight, and rail transport are not competitors—they are tools.

The most successful businesses:

-

Understand their products

-

Know their customers

-

Align logistics with strategy

When transport decisions support—not fight—your business model, logistics becomes a growth engine rather than a cost burden.

The right choice is rarely the fastest or the cheapest.

It’s the one that fits.