1. What is a linear crossbelt sorter

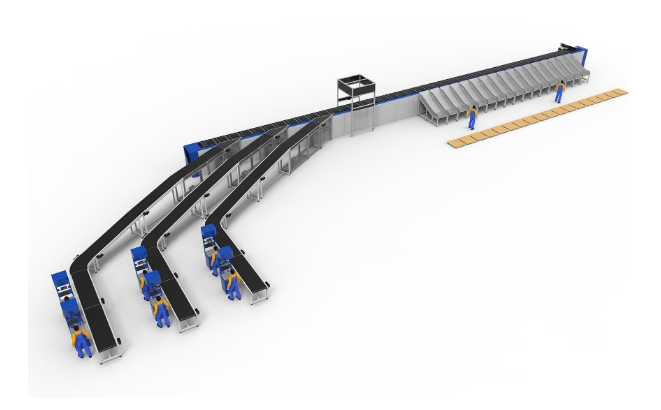

Straight line sorter, is a layout of linear courier crossbelt sorter, and courier centers and one or two levels of distribution in the circular crossbelt sorter operation and layout are different, his existence is mainly for the express industry to solve the end of the port of dispatch and born. Has a small footprint, high sorting efficiency, labor saving, energy saving, easy to operate and so on. With the sinking of the layout of the automation equipment of the express delivery enterprises, the linear sorter has also entered more people’s vision, and has been favored by the automatic sorting users!

2. The advantages of linear sorter

Linear sorter as “small and medium-sized outlets sorting magic weapon”, has obvious advantages:

Small footprint: linear modeling, minimum footprint of only 300 square meters or so, can greatly save space and rent;

High sorting speed: line running speed 1.0m / s-1.5m / s multi-band adjustable, to achieve the real efficiency of 8000 tickets / hour sorting efficiency;

Simple operation on pieces: it can be operated manually on pieces, or directly accessed to the telescopic machine and belt section, realizing automatic piece automatic sawing and automatic drop frame, reducing manpower investment;

High sorting accuracy: the top scanning barcode recognition rate of 99%, automatic identification, automatic drop frame, high accuracy, to avoid the fatigue of manual operation, errors caused by the wrong penalty;

Strong customization flexibility: customized design can be carried out according to the needs of different sites, sorting trolley specifications 250mm/400mm/500mm optional, grid width 700mm/750mm/1000mm/1500mm optional, modular assembly of trolley rails, the number of grid can be flexibly assembled to support inbound/outbound operations.

Short delivery cycle: thanks to the standardized composition structure, lightweight overall shape, linear equipment from production, transportation, assembly to commissioning and use, the fastest only 7 days, can quickly meet the user’s needs;

Cost-effective: the input cost of linear equipment is lower than that of loop line, and at the same time, it can greatly alleviate the efficiency pressure caused by the rising operation volume, optimize manpower allocation, complete the task of sorting and delivering pieces more efficiently, and promote the benign operation of outlets.